A cross-functional team, including forklift drivers, supervisors and dispatchers, recently came together to review the process of truck loading and unloading at CHEP’s Wiri service centre in order to mitigate potential hazards and risks for truck drivers in high forklift traffic area.

A cross-functional team, including forklift drivers, supervisors and dispatchers, recently came together to review the process of truck loading and unloading at CHEP’s Wiri service centre in order to mitigate potential hazards and risks for truck drivers in high forklift traffic area.

Using the Kaizen principles of process review and improvement, the team mapped out workflow and timed all activities from the moment a truck enters the site, through loading or unloading pallets, to leaving the site.

Wiri Service Centre Manager, Ed Fili, said, “Our objectives were to improve safety by limiting truck driver and forklift interaction and improve site efficiency. We worked with the entire site to review processes and identified crossovers and inefficiencies that could be stripped back to reduce truck waiting times and improve the load/unloading times – while at the same time addressing safety issues.”

“We approached this project much like a Formula One pit crew would to shave vital seconds off a pit stop in order to get the car back on the track as quickly and safely as possible,” Fili said.

The team identified that there was significant overlap of driving and pedestrian zones and double handling of pallets. The average truck load/unload time was 25 minutes.

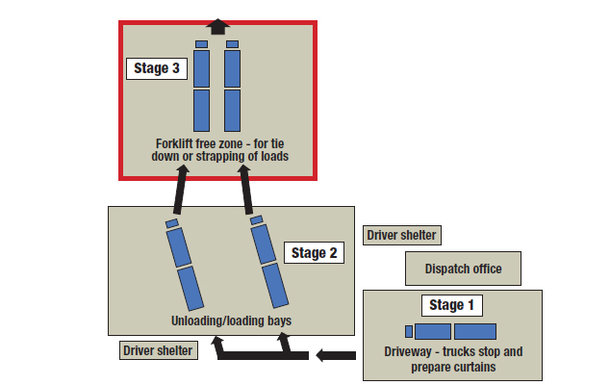

The proposal of a three-stage process and reconfiguration of the Wiri site was accepted and a trial implemented to assess the impact of these changes. The new site configuration included the relocation of the dispatch office and physical marking out of three distinct areas, each for a specific activity (see diagram).

- Stage 1 – The driver prepares the vehicle such as opening side curtains, removing tie downs or straps and completes the paperwork so that the truck enters the next stage in ready condition.

- Stage 2 is the loading/unloading area. Once a loading bay is vacant and ready to receive a vehicle, the driver moves the truck forward slowly into a designated bay. One forklift places a truck stop sign in front of the truck to signal zero truck movement during loading/unloading process. This forklift operator takes the paperwork and guides the driver into the safety of one of CHEP’s new driver safety shelters, ensuring the 6 metre exclusion zone around the truck is completely clear. The forklift drivers then move in to load or unload the truck. Up to two forklifts are dedicated to each vehicle, taking responsibility to move pallets to their final destination and reduce handling. After serving, one forklift operator removes the truck stop sign and signals the truck driver to return to the vehicle, while the other forklift stops on the side. This ensures zero forklift movement in the bay while the truck driver walks through it.

- Stage 3 – The driver moves the truck forward slowly into a completely forklift-free zone. At this point the driver can secure the load and close the curtains, able to move around the vehicle freely.

The team at Wiri took the time to fully inform and educate all incoming drivers of the new trial process; providing brochures, engaging in one on one discussions and even showing truck drivers videos of the proposed process improvements. Both the truck drivers and forklift operators recognised the benefit of the exclusion zone and saw that the shift to a three-stage process would reduce the risk of accident or injury as well as reduce wait times.

Compliance with the new process demonstrated a 40 percent reduction in serving time – with average loading/unloading times falling from 25 to 15 minutes. As a direct result of the success of the trial and positive customer feedback, the new yard design and processes were adopted at Wiri and have since been implemented at CHEP service centres across the country.

Truck drivers have valued CHEP’s ongoing commitment to Zero Harm and the establishment of safe zones at CHEP service centres. In order to support other businesses to improve their safety records, CHEP is currently sharing this safety improvement process with industry partners.